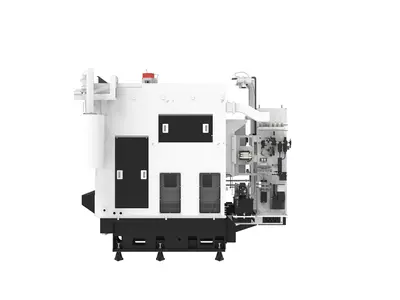

High rigidity vertical #40 column traverse machine

Flexibility to accommodate various jigs, tables, and transfers

• This is a line-oriented machining center with column traverse type axis travel. Long tools and large-diameter tools can be handled with ease, and combined with the column up, this is a highly rigid machine that can be used in all kinds of processes. The series also includes an AWC (automatic workpiece changer) type.

Main features

• Flying box structure and high rigidity

The flying box structure evenly dissipates thermal expansion, and the shaft drive is located above the machining area to minimize the effect of chips. 3 Y-axis guides are supported on each side to increase rigidity at each position, and the ball screws, together with the center arrangement of each axis, enhance stability.

Supports a wide range of processes with ample specifications

• The #40 machine can handle a maximum tool length of 300 mm and a maximum tool diameter of Φ300 mm. Combined with TILT & INDEX 5-axis specifications and column up, the machine can handle a wide range of workpieces. High rigidity 6000min-1 spindle option is available.

Column traverse type for efficient chip handling

• The inside of the machining chamber is designed to be sloped to allow chips to fall smoothly and to be covered to prevent chips from entering the shaft drive unit and table drive unit. The shaft drive unit is located outside the machining chamber and is designed to prevent chips from entering.

Line-oriented and flexible to your requirements

• We can coordinate 4/5 axis tables, various automatic conveyors, jig design and manufacturing, workpiece test processing, jig stockers, workpiece stockers, AGVs, deburring units, and various other lines.

Stroke X/Y/Z .......................... 600 / 450 / 450 mm

Spindle taper type .................... BT-40 / HSK-A63 Type

Spindle speed ......................... 200~12,000 min-1

Spindle motor ......................... 11 / 7.5 Kw

Fast forwarding speed ................. 50 m/min

Number of tools stored ................ 32 pcs

Max. tool length/Max. tool diameter ... 300 / Φ300 mm

Control unit .......................... FANUC Maker

Machine Size .......................... W2,180×D3,300×H3,450 mm

Machine mass .......................... 9,000 Kg

We use cookies to improve your experience. Privacy Policy.