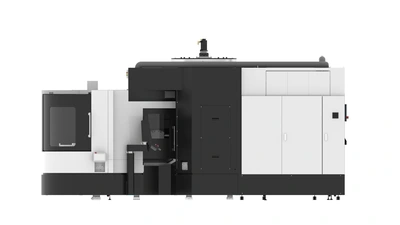

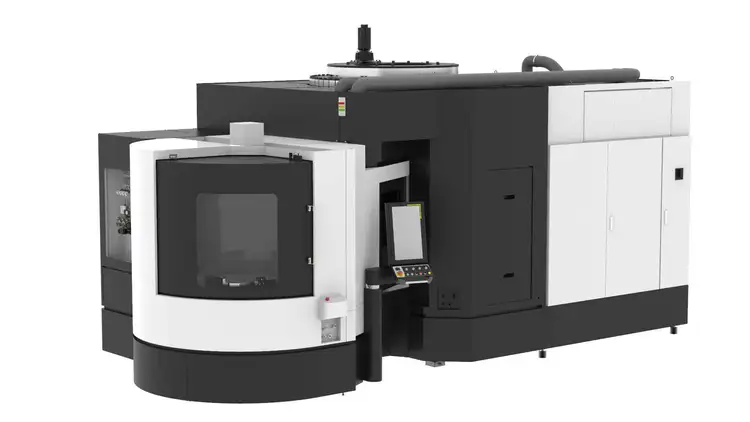

High-efficiency horizontal 5-axis machining center

All with high efficiency.

• Under the theme of "High Precision, Safety, and User Friendly," we have integrated spatial accuracy, better chip management, and operator consideration into 5-axis control machine.

We also prepared large-capacity tool magazine and pallet changing system for long-time unmanned operation as an option to support labor saving.

Main features

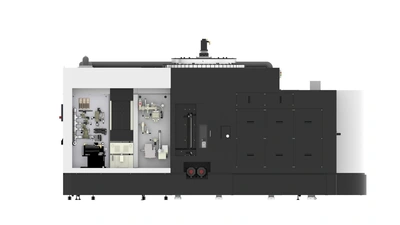

Improved chip evacuation with overhead machining posture

• The table is in an upside-down position, allowing chips to settle into the trough directly below without any obstructions. This also reduces the accumulation of chips on the workpiece and jig, which results in a lower failure rate and reduces manual handling for cleaning the machining chamber.

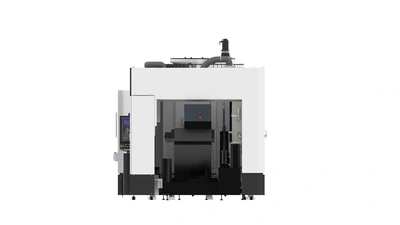

Cantilevered table structure for improved setup

• There is no tailstock on the operator's side, which improves operability and confirmability, including centering confirmation. Also, each time the A-axis swings, chips fall from a wide range of angles, preventing chips from accumulating on the jig. A hydraulic port for the jig is also available as an option.

Spatial accuracy compensation improves reliability and work efficiency

• Positioning compensation is not limited to the usual one linear XYZ axis, but spatial compensation is numerically input using special software. This makes it easy to use the program output from CAM immediately and improves ease of use and setup.

User-friendly

• The height from the floor to the top of the pallet is kept at 1,120mm, which is high enough to allow step-less operation, and the door opening on the take-up side of the 2-sided pallet is as wide as 1,250mm, opening in a fan shape at the top. The main operation panel is also located in an easy-to-see position for improved operating efficiency.

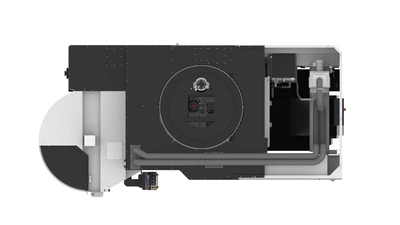

pallet ............................... 500 × 500 (2-sided swivel type, top side: M16 tap) mm

Stroke XYZ ........................... 800 / 800 / 900 mm

Spindle taper type ................... HSK-A63 Type (CAT40, BT40 Available)

Spindle speed ........................ 100~20,000 min-1

Spindle motor ........................ Output (10 min / continuous) 37 / 26 Kw

Fast forwarding speed ................ 60 m/min

Number of tools stored ............... 60 (220 opt.)

Max. tool length/Max. tool diameter .. 400 / Φ250 mm

Control unit ......................... FANUC FS-31i-B5 PLUS series Type

Machine Size ......................... W2,985×D6,175×H3,280 mm

Machine mass ......................... 18,000 Kg

We use cookies to improve your experience. Privacy Policy.