Environmentally friendly, energy-saving #30 horizontal machine

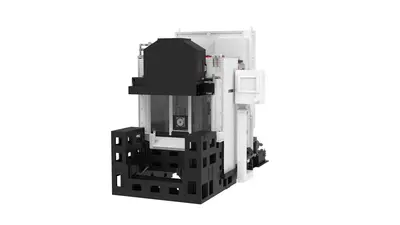

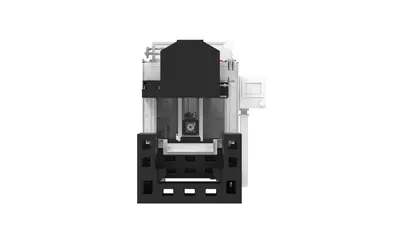

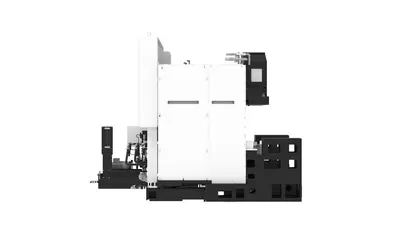

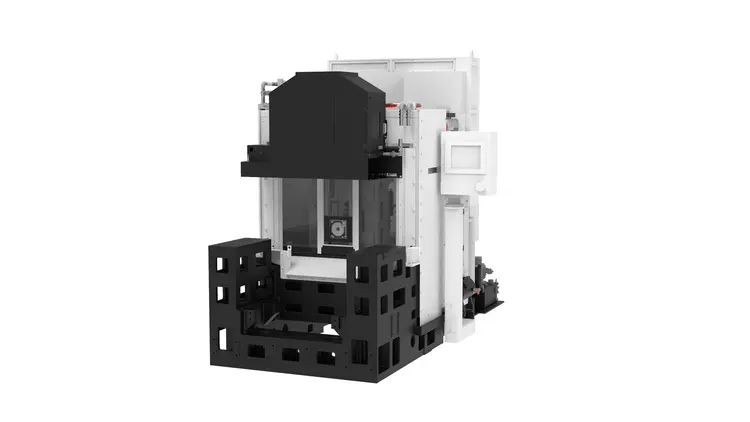

Simple, Slim and Compact machines

• Energy-saving and space-saving machine that enables a combination of machine size that matches small workpieces and a low-floor gantry. This is a line-oriented machining center that matches the times and is friendly to both the factory and the environment.

Main features and specifications

Energy conservation

• The spindle clamping mechanism is hydraulic-free. The machining chamber is minimized to reduce the amount of coolant, which together with the lack of hydraulic pressure reduces the amount of electricity consumed.

Multi-product jig support

• Komatsu NTC's original standard tilt table can be easily used for additional axes. The common jig base supports the common use of jig bases and quick jig changeover.

Simple, Slim, and Compact with low-floor gantry transfer

• The combination of minimizing the machine height by minimizing the machining chamber and NTC's low-floor gantry transfer reduces the transfer height to 1650mm. The gantry stroke is shortened to 400 mm, enabling high-speed loading and unloading for higher productivity.

Extensive automation support

• We can coordinate 4/5 axis tables, 2-sided pallet changers, various automatic transfer devices, jig design and manufacturing, workpiece test processing, jig stockers, workpiece stockers, AGVs, deburring units, and various other lines.

Stroke X/Y/Z ......................... 400 / 300 / 300 mm

Spindle taper type ................... BT-30 Type

Spindle speed ........................ 200~12,000 min-1

Spindle motor ........................ 5.5 / 3.7 Kw

Fast forwarding speed ................ 48 m/min

Number of tools stored ............... 16 pcs

Max. tool length/Max. tool diameter .. 200 / Φ80 mm

Control unit ......................... FANUC Maker

Machine Size ......................... W1,200×D2,200×H2,000 mm

Machine mass ......................... 2,700 Kg

We use cookies to improve your experience. Privacy Policy.