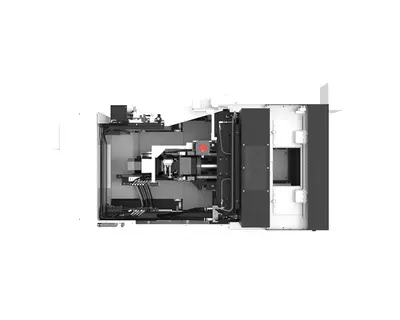

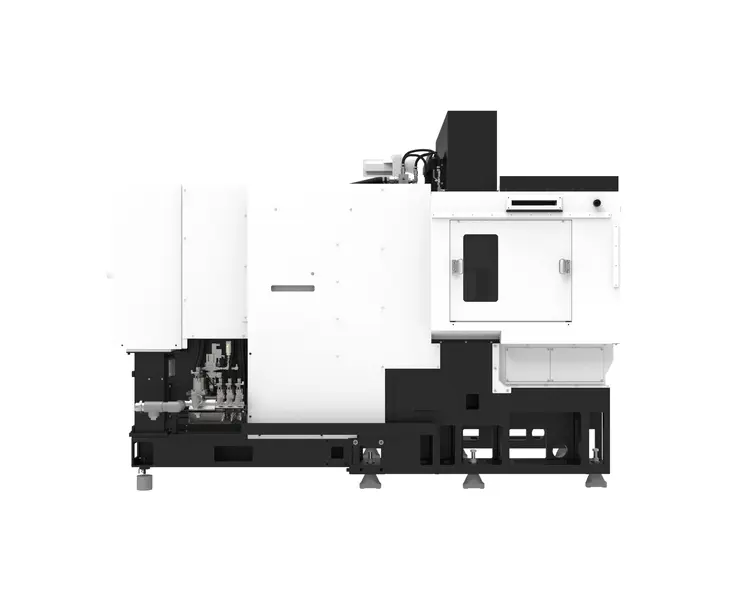

Shaft machining #40 horizontal machining center

Small machining center for crankshaft machining line

• This is a dedicated machining center with a reduced Y-axis stroke for crankshaft drilling, double-ended face, centering, and keyway machining. The dedicated design, in combination with the low-floor gantry transfer, minimizes the space required for the machine, including its height.

Main features

Compact & rigid structure

• By limiting the Y-axis stroke to the required amount, sufficient rigidity is secured for steel and cast metal machining. In addition, the machine height has been reduced, and the machine volume ratio has been reduced by 33% compared to the conventional machine.

Increased productivity

• The spindle motor is a direct-coupled type and can handle 11/7.5Kw to support highly efficient machining due to the increased rigidity of the machine. Chips are discharged smoothly from the wide trough by adopting a nadir type bed, reducing manual handling in the machining chamber.

Simple, Slim, and Compact with low-floor gantry transfer

• The combination of minimizing the machine height by minimizing the machining chamber and NTC's low-floor gantry transfer reduces the transfer height to 1650mm. The gantry stroke is shortened to 400 mm, enabling high-speed loading and unloading for higher productivity.

Turnkey support for crankshafts

• Turnkey support is provided by a single NTC company. We also provide crankshaft balance measuring machines, pin mirror oil hole drilling machines, cylindrical grinders, orbit grinders, low-floor gantry conveyors, workpiece stockers, inspection equipment, and more.

Stroke X/Y/Z .......................... 500 / 200 / 400 mm

Spindle taper type .................... HSK-A63 Type

Spindle speed ......................... 200~8,000 min-1

Spindle motor ......................... 11/7.5 Kw

Fast forwarding speed ................. X / Z=48 Y=30 m/min

Number of tools stored ................ 20 pcs

Max. tool length/Max. tool diameter ... 200 / Φ100 mm

Control unit .......................... FANUC Maker

Machine Size .......................... W1,350×D3,200×H2,415 mm

Machine mass .......................... 3,800 Kg

We use cookies to improve your experience. Privacy Policy.