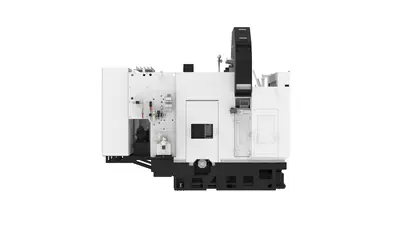

Horizontal machining center #40 for mass production

Flexible line-oriented machining center

• Continuous machining operation requires high speed and stability, and the N40Hi is a three-point support bed that ensures rigidity while minimizing the number of units and weight. Tool change is done by a magazine-direct system with fewer components. Maintenance is also enhanced by the centralized equipment layout.

Main features and specifications

Lightweight, high-speed and stable axis configuration

• The Z-axis has a column-feed structure with enhanced loop rigidity. The weight of the Z-axis moving unit is 36% lighter than that of conventional machines. In terms of rigidity, the bed shape is a 3-point support bed with a chip nadir structure and rigidity analysis to enhance stability.

Adoption of direct tool change magazine

• To ensure high uptime and stability, the tool change is done by direct magazine change without the use of an arm. The magazine shutter is located at the top of the Y-axis stroke, and the shutter gap is equipped with a coolant stream to prevent chips from entering, ensuring stable and continuous operation.

Improved maintainability

• Each unit is designed for quick recovery in case of trouble. The spindle clamping unit can be replaced from the entire surface of the spindle. Each motor can be replaced from the outside of the machine. Detectors are arranged for easy checking and designed to speed up checking and recovery time.

Extensive line support

• We can coordinate 4/5 axis tables, 2-sided pallet changers, various automatic transfer devices, jig design and manufacturing, workpiece test processing, jig stockers, workpiece stockers, AGVs, deburring units, and various other lines.

Stroke X/Y/Z ......................... 500 / 500 / 400 mm

Spindle taper type ................... HSK-A63 Type

Spindle speed ........................ 100~12,000 min-1

Spindle motor ........................ 11 / 7.5 Kw

Fast forwarding speed ................ 60 m/min

Number of tools stored ............... 20 pcs

Max. tool length/Max. tool diameter .. 270 / Φ160 mm

Control unit ......................... FANUC Maker

Machine Size ......................... W1,720×D3,830×H2,785 mm

Machine mass ......................... 7,000 Kg

We use cookies to improve your experience. Privacy Policy.