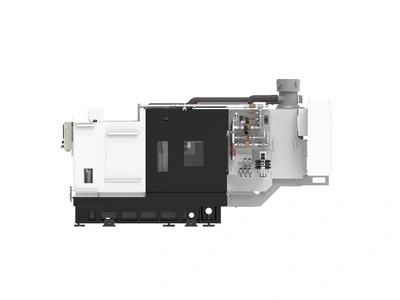

Ultra compact, high production, high utilization

Concept machine dedicated to gantry transfer

• Compact machines developed for high productivity and high uptime are equipped with a specially designed gantry transfer system. The machine and gantry interlock with each other to minimize strokes and reduce non-machining time. It combines visibility and high productivity.

Main features

High-speed workpiece loading and unloading with dedicated gantry transfer equipment

• The Y-axis exchange position at workpiece loading/unloading is at the up end, minimizing gantry arm travel and reducing workpiece loading/unloading and non-machining time. This shortens workpiece loading/unloading and non-machining time and increases productivity.

Compact & High Rigidity

• The bed, column, etc. are analyzed by FEM, and the Y-axis movement system is designed to move the table up and down by double holding. Ball screws and double guides are arranged on each side of the table for high-speed, high-precision synchronization.

Independent machining chamber and highly efficient chip handling

• Independent machining chamber with both table holding type and spindle quill moving type. The bed is also shaped like a large trough to collect chips directly under the table. At the same time, manual handling in the machining chamber and coolant consumption are reduced.

Compact yet compatible with 5-axis specifications

• Tilt and indexing tables can be mounted in a compact machining chamber to accommodate 5-axis indexing. The same machine can be used to configure a line, and together with the low-floor gantry, visibility and maintainability are also enhanced.

Stroke X/Y/Z ......................... 500 / 500 / 500 mm

Spindle taper type ................... HSK-A63 Type

Spindle speed ........................ 200~12,000 min-1

Spindle motor ........................ 11 / 7.5 Kw

Fast forwarding speed ................ 60 m/min

Number of tools stored ............... 20 pcs

Max. tool length/Max. tool diameter .. 320 / Φ165 mm

Control unit ......................... FANUC Maker

Machine Size ......................... W1,730×D4,075×H1,950 mm

Machine mass ......................... 9,400 Kg

We use cookies to improve your experience. Privacy Policy.